Coaching

Healthy House Electrical

The electrical rough-in for our healthy house was started after the roof was on enough to protect the wiring from getting wet.

The first step was to install electrical boxes for the following:

- Outlets

- Switches

- Telephone

- Cable TV

- Computer network

- Doorbells

- Smoke alarms

- Surface-mounted ceiling lights

Electrical boxes are usually a major source of air leakage in typical homes. To keep everything air tight, we used special air tight electrical boxes made by Nutech Plastics. These have one gasket around the edge that contacts the drywall, and another around the area where the wires enter the box. A small hole is cut in the second gasket to allow the wire to be inserted into the box. Then the hole is sealed with 100% silicone caulk to keep it air tight.

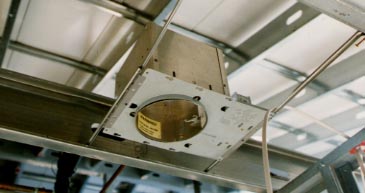

Although surface-mounted fixtures normally use a standard electrical box, "can" type down-lighting does not. We used a really great air tight can-type down-light from Juno Lighting that solved this problem. The following picture shows one of the lights installed in the ceiling.

I originally wanted to run all of the house wiring in conduit. Several companies make armored cable (a type of "pre-fab" conduit), which is sometimes used in commercial applications. Most of that cable isn't air tight, though. A few companies do make an air tight version of armored cable, but it is pretty costly. There are two reasons why conduit is a good idea. First, it protects the wire from catching fire, and it prevents fire from spreading along the wires. Conduit also keeps the (strong) smell of the wire from getting into the house. It would have cost about $5,000 to run all wiring in regular conduit. We decided we could save a little money by using standard romex instead. What we did was to buy the wire well in advance of installing it, to let it off-gas as much as possible. It turns out that the insulation material that we used inside the exterior walls and in the attic is fire proof. Because it was sprayed on in a semi-solid form, it surrounded the wire and provides a degree of fire protection. Finally, we are using foil-backed drywall to help keep any residual wire odor (and other odors from outside) from entering the house. Without foil backing, drywall is slightly permeable, and it is possible that a strong odor could seep through the material, especially over a period of months or years.

To keep the romex from getting damaged, it is run through red plastic rings that sit inside holes in the steel studs. Our main interior junction boxes are shown in the photo below.

To help minimize exposure to electromagnetic fields (EMF), wire in the bedrooms was run only vertically where possible. Long horizontal runs would have made it difficult to avoid being next to the wires and their associated EMF. There is some evidence in the scientific literature that EMFs can cause or aggrevate immune system disorders, so it made sense to limit our exposure where possible.

We did something a little different with the telephone and cable TV wires. Instead of connecting each outlet to every other outlet, such as is done in most homes, a single wire was run from each outlet to a central electrical room. This gives us maximum flexibility. It would allow us to install a fancy video system later on, or a central telephone system with an extension for each phone, for example. We also ran wires from the doorbells, doorbell switches, outdoor sprinklers and ventilation controls back to the electrical room for tie-in to a future home automation system. Part of the wiring in the central electrical room is shown below.

Ventilation System

Here's a picture of the ductwork for our ventilation system. The ducts are bare aluminum, and are run through the attic space. They couldn't be run under the house, since it was built on a foundation. Bare aluminum was used to avoid the fiberglass insulation that commonly surrounds ducts. The ducts were insulated instead with an aluminized bubble wrap (not shown here).

The air handler and filter for the house is shown below. The filter uses a 3HP motor. It contains about 500 pounds of activated carbon, along with pre-filters and a final HEPA filter stage, so that it removes dust/pollen/mold, as well as chemical pollutants. Unfortunately, the filter ended up costing about $500/month (for electrical alone) to operate, so we didn't use it as much as I would have liked. The photo below was taken before the air conditioner was installed (it sits on the concrete pad, to the right of the stainless steel filter box). This picture was also taken before the filter was hooked up to the house. There are ducts running from each end of the filter, up to the two square connection points that can be seen just above the filter.

Articles

diagnosis

detective

MCS/EI/CFIDS

protocol

oxygen O2MT

Healthy House

guidelines

location

foundation

floorplan

framing

flooring

electrical

plumbing

roofing

windows

siding

kitchen

Supplements

carnitine

cetyl myrist.

coq10

d-glucarate

glucosamine

IP6

Lipoic Acid

Vitamin E